Products

Asprova APS

Production planning that’s swift, smart and down to the second

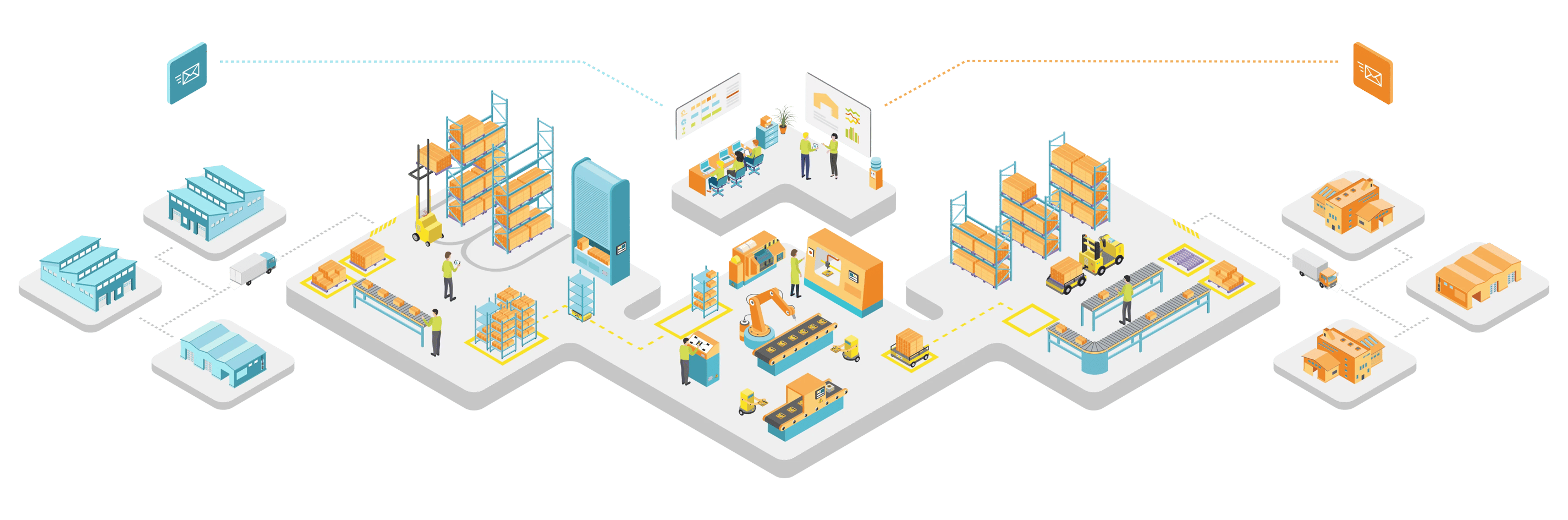

Asprova APS gives you full control over your production plan, both at a single plant and at every branch in your corporation. It can factor in every production constraint. And as Asprova’s largest partner in Europe, Aimtec guarantees problem-free Asprova deployments.

- 1200+

DEPLOYMENTS

- 7/2

- SUPPORT

- 9

- YEARS OF DEVELOPMENT

Where will Asprova APS help you?

Planning

Logistics

Manufacturing

IT

Why Asprova APS?

A global APS leader

Harness the potential of a world-class high-end system that’s among the three most widely used worldwide.

Standardisation throughout your corporation

Create your own standardised production planning model based on predefined templates and supervise their use throughout your corporation.

A flexible response to manufacturing constraints

With Asprova APS, you gain the ability to flexibly handle unexpected situations, making you a more reliable supplier.

A premium partner

The Asprova APS system is a Japanese product with a global partner network where individual partners provide mutual support. We’ve been working with Asprova since 2012, and today we’re the largest European premium partner for this system’s deployment around the world.

Our team includes consultants for planning and management of production, simulation consultants and a supporting development team. We specialise in the automotive corporations segment.

Frequently Asked Questions

- Is it possible to verify that APS is the right choice before deployment?

-

Absolutely. It’s very important to us for your APS to provide your business with true added value. So we verify every solution in full using a plant-dependent model even before it is deployed.

- How does Asprova APS maintain high data quality over the long term?

-

We load in all data from its individual sources and verify it in advance to ensure it’s truly been prepared at sufficient quality for the advanced planning system. Our reporting tools also let you see summary visualisations of data quality.

- Does Asprova APS enable supply chain planning?

-

Alongside planning production, Asprova APS can also plan supply chains thanks to an integrable SCP module. It gives your central planner up-to-date information on other plants’ status.

- How quickly can Asprova APS calculate a production plan?

-

This system is designed as a monolithic application, and the production plan is calculated in computer memory – enabling calculation in seconds.

“Asprova APS integration can complement ERP.

One benefit of Asprova APS is that customers can integrate it to complement an ERP system – typically SAP – and then tailor it precisely to themselves without lengthy programming.”

Pavel Boháč APS Solutions Director

Interested?

Want to learn more about Asprova APS? Eager to see some sample deployments? Contact our specialists.

Other Asprova APS specifics

- Standardisation

-

Everyone can work with the same software, documentation and reporting.

- Inter-plant planning

-

Asprova APS enables planning throughout your supply chain.

- High-speed calculations

-

Plan preparation is nearly instant thanks to in-memory calculation.

- Autonomous client

-

You can meet new customer requirements without calling in a planner.

- Unified reporting

-

Management can compare individual plants’ KPIs.

- Data purity

-

Asprova APS works with purified data from transparent sources.

Case study

Digitalising the planning of manufacturing processes

Magna manufactures plastic components for passenger cars. This company has some of the toughest and most complex manufacturing processes in the industry. Asprova APS provides efficient planning at Magna.

Aimtec Insights

Get in touch

Want to learn more about Asprova APS? Contact an Aimtec specialist. They’ll show you further specifications for this planning system, along with example deployments.

Václav Kalina Business Consultant Production Planning Solutions