Solutions

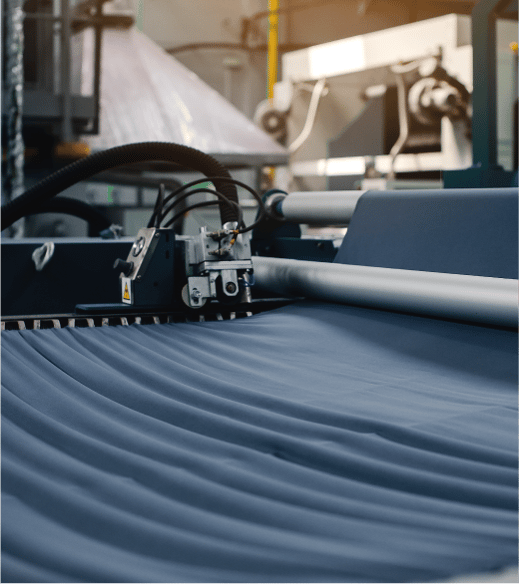

Manufacturing

Execution System

Collect the latest data and monitor

production processes in real time

Maximum performance and a clear vision at less cost

- Increased production performance

-

Timely discovery and elimination of selected downtimes and performance-reduction reasons cuts down on WIPs and raises overall efficiency.

- Precise data for worker planning and evaluation

-

A detailed digital image of production lets you acquire precise data and then use it when making decisions and setting remuneration.

- Decreased record-keeping costs

-

Paper-free records save costs during subsequent administration and data rewriting – and also save time for managers.

- A clear view of worker qualifications

-

We help you track, manage and improve workers’ qualifications for manufacturing work centres and processes. And increase their motivation.

- QMS, MMS, WMS and APS connections

-

Real-time management of work centres, machines and people, plus linked processes in quality, maintenance, logistics and production planning, all as one unit.

Our customers

Our MES solution’s benefits will win you over

OEE – quality, performance, availability

Timesheets; correct and defective units; work times and downtimes; teamwork; multi-machine operation.

Maintenance

Regular, preventive and ad-hoc maintenance; maintenance response requests and registration; filing and tracking of maintenance tasks.

A skills matrix for every work centre and every machine

Skill expiration dates; increases and decreases to skill levels; training; skill checking before work begins.

Escalations/notifications

The MES can notify designated persons of atypical states and incidents, escalate after solution deadlines and register responses and reasons.

Inter-operation quality

Verification plans; check frequencies; regular and spot checks.

Traceability

A register holding serial numbers for products, utilised parts and materials, processing parameters (machines), and part histories.

“Implementing digital monitoring of Overall Equipment Effectiveness (OEE) doesn’t slow down production, nor does it restrict your operators. It lets you send data to machines and receive important parameters for future managerial decision-making in return.”

Václav Zajíček DCIx Consultant

Interconnect production with other systems

SAP SOLUTION

MES within SAP system

Gain the benefits of a MES solution directly within SAP system.

OTHER SOLUTIONS

MES as an independent solution

Gain the benefits of a MES solution

inside Aimtec DCIx.

Supplement your MES solution with Zebra devices

Zebra offers a broad portfolio of automatic identification products and services. We’ll help you choose the right technologies.

Case study

Digitalisation of manufacturing and logistics; SAP roll-out

A comprehensive digitalised traceability, sequencing and logistics solution for the majority of the group’s branches.

Aimtec Insights

Get in touch

Want to learn more about this solution? Contact an Aimtec specialist. They’ll show you all its specifics, along with examples of specific deployments.

Daniel Choc Business Consultant Shopfloor Digitalization & Automation Solutions