Products

FlexSim

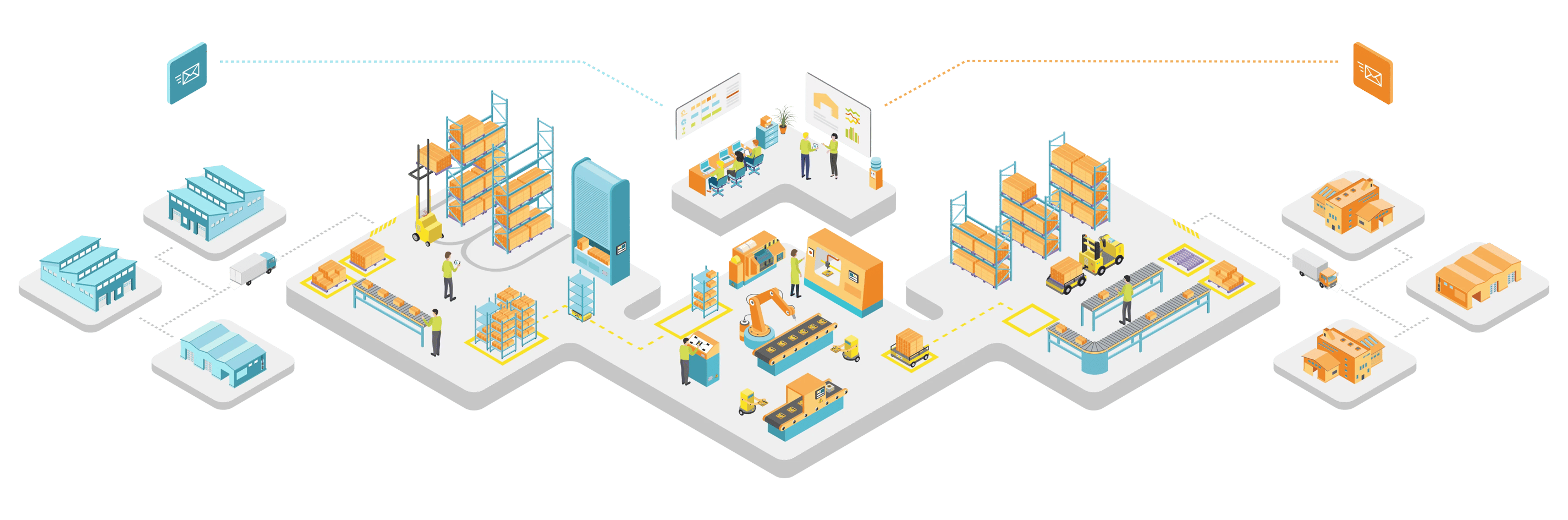

Simulate and optimise your processes before their implementation

FlexSim lets you simulate and compare various scenarios in a virtual environment risk-free. Use 3D process visualisation, verify hypotheses and gain certainty before you make any changes. With advanced analytics, you have a tool for lowering costs and raising efficiency – turning uncertainty into a strategic advantage.

- 8+

YEARS OF EXPERIENCE

- 7/2

support

- 0D

- vizualisation

How can FlexSim help you?

Automation

With FlexSim, you can easily test the management of automated equipment and warehousing strategies (e.g. via ABC analysis). Simulate WMS integration and verify the performance of the whole system – including complex technologies such as ASRS, AutoStore, AGVs, AMRs and robots.

Manufacturing

Logistics

Why FlexSim?

A tool for strategic decision-making

FlexSim creates realistic 3D models of real-world processes that reflect actual operations. This gives you a foundation for informed decisions that factor in both operational and financial factors.

User-friendly

Drag-and-drop workflow for easy modelling of manufacturing and logistics processes. A complete object library with built-in logic, plus an environment for creating additional logic without coding.

Ready to use right away

Includes pre-configured modules for easily extending modules to add conveyor systems, AGVs, warehouse systems and more. Our expertise gives us the ability to deliver solutions quickly, efficiently and with high added value.

Frequently Asked Questions

- Who is FlexSim for?

-

FlexSim users typically focus on process improvements in manufacturing, logistics or transport. FlexSim is an ideal tool for anyone who wants to better understand or optimise production and logistics. Its typical users include production and logistics managers, project managers, analysts, quality specialists, operations staff and more.

- Is FlexSim powered by artificial intelligence (AI)?

-

FlexSim uses elements of AI, for example reinforcement learning for advanced optimisation of decision-making processes. That means models can be both simulated and intelligently improved based on data and the goals you’ve defined.

- How do I gather the data needed to build a simulation model?

-

You don’t have to do it on your own. Our experts will help you determine what data is needed, where to find it and how to prepare it for use in the model. We make the most of your existing systems and help you fill in the rest, so that the model is as accurate and the results as useful as possible.

“FlexSim helps us make decisions with great peace of mind. Instead of relying on estimates, we have hard data supported by visualisation – whether we’re dealing with layout changes, operator numbers or warehousing strategies. We can clearly see what will work and where problems might turn up. It’s an invaluable tool for anyone who needs to make smart and timely decisions rather than relying on guesswork.”

Martin Kraus Modeling and Simulation Consultant

Interested?

Want to learn more about FlexSim? Eager to see some example deployments? Contact our specialists.

Other special features in FlexSim

- Flexibility and scalability

-

From simple lines to whole factories. FlexSim can easily be adapted to a variety of sectors and business sizes.

- Risk-free change testing

-

Layout changes, new technology implementation, or shift reorganisation – everything can be tested in advance without affecting live operations.

- Alignment of production, logistics and planning

-

Connect different parts of your business into a single digital model. Coordinate production, warehousing and deliveries.

- System performance analysis

-

Determine maximum system throughput with stress tests. Identify bottlenecks that prevent further efficiency gains.

- ABC Analysis

-

Right inside the model, without the need for additional tools.

- Digital Twin

-

Create a living digital model of your operation in a virtual environment that reflects reality.

- A popular simulation tool

-

This is one of the most widely used simulation tools, developed in the USA under the Autodesk umbrella.

- Simulation without disrupting live operations

-

Test different scenarios safely – outside of live operations. Rely on tested solutions.

Case study

In the Rhythm of Automation: Smart Logistics in the World of Vinyl Records

Using simulations in the FlexSim tool, it was possible to verify that the proposed automation solution can handle full capacity and achieve the planned performance. This gave the company confidence that the investment in modern logistics will deliver the expected results.

Get in touch

Want to learn more about FlexSim? Turn to an Aimtec specialist. They’ll show you further specifications, including example deployments.

Václav Kalina Business Consultant Production Planning Solutions

.png?width=239&name=GZ%20Media_1%20(1).png)