Solutions

Manufacturing

Operations Management

Check connected manufacturing processes

and optimise manufacturing efficiency

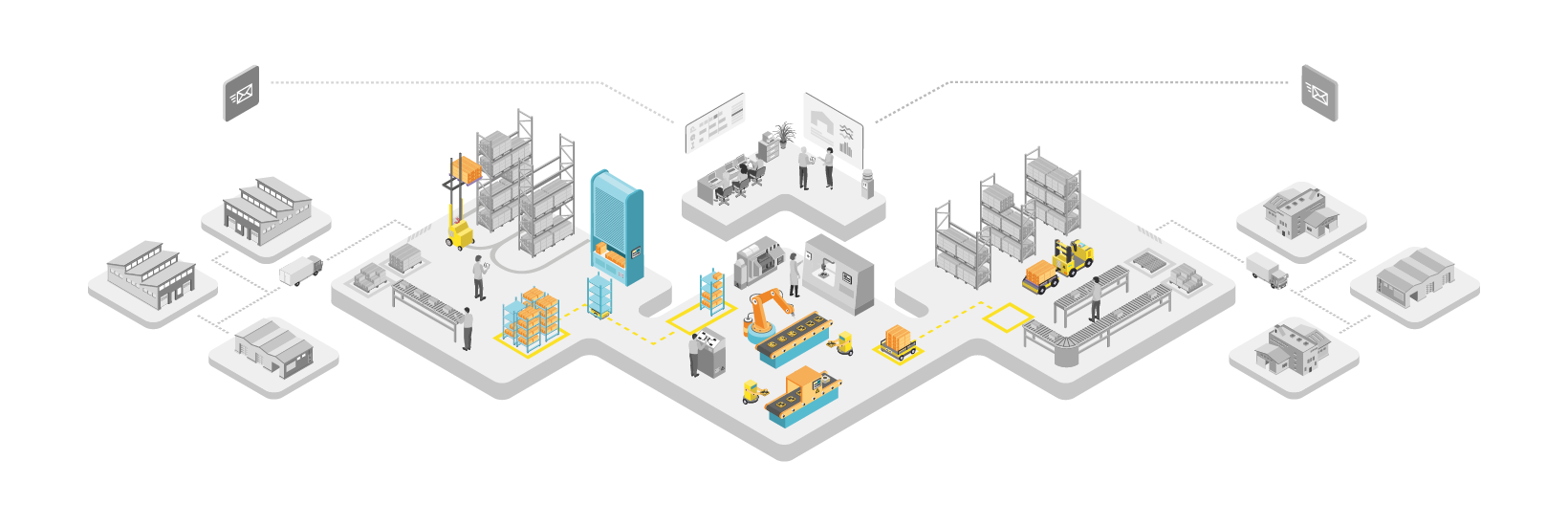

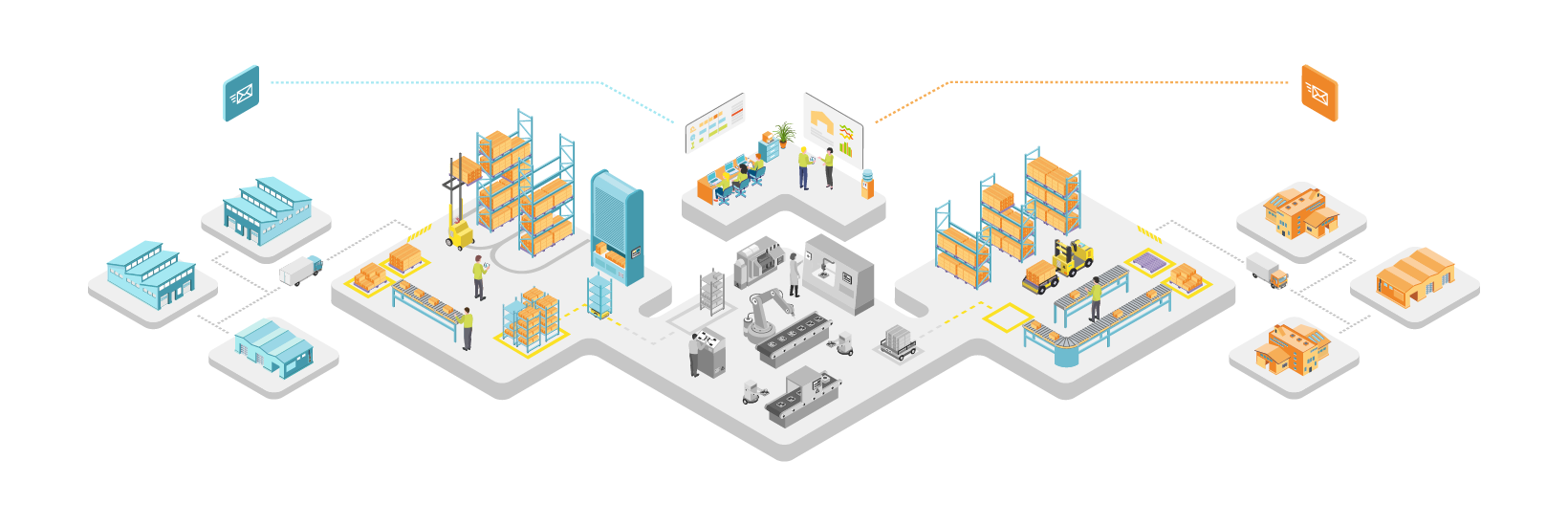

Horizontal and vertical integration

- Increasing overall manufacturing efficiency

-

Losses caused by downtimes, reduced performance or an increased scrap rate are minimised. Material intake in production is synchronised, and production runs smoothly.

- Immediate reactions to states of production

-

Production parameters are constantly monitored and non-standard states are escalated instantly. No non-standard units are admitted into further operations, and every non-standard status is checked by a qualified worker.

- Horizontal and vertical interconnection

-

Every instruction goes automatically from control systems to the shop floor, straight to equipment and machines. Follow-up processes and operations are interconnected to achieve maximum efficiency.

- A digital platform

-

An efficient tool for interconnecting your information system with all your technologies. It amounts to a layer for intelligently managing processes, people and technologies. Everything is easy and quick to configure.

Our customers

One solution for your entire factory

.png?width=1640&height=550&name=Manufacturing%20Operational%20Management%20(MOM).png)

.png?width=1640&height=550&name=Manufacturing%20Execution%20System%20(MES).png)

.png?width=1640&height=550&name=Advanced%20Planning%20and%20Scheduling%20(APS).png)

.png?width=1640&height=550&name=Quality%20Management%20System%20(QMS).png)

.png?width=1640&height=550&name=Warehouse%20Management%20System%20(WMS).png)

Manufacturing Operations Management (MOM)

A smart layer that connects the entire supplier/customer chain and gives you a precise instant digital image.

Manufacturing Execution System (MES)

Comprehensive production-data collection and management. These systems manage, monitor and synchronise manufacturing processes in real time during the transformation of input material and raw materials into semi-finished goods and finished products.

Advanced planning and scheduling

Operative planning and organisation of production. Supply-chain planning – for example planning of suppliers, contractual manufacturers and refurbishers.

Quality Management System (QMS)

Administration and management of quality principles and standard operating procedures (SOP). This includes customer requirements, quality documents, audit procedures and protocols, discrepancy/risk management and more.

Warehouse Management System (WMS)

Management of internal logistics processes along with parts, materials, semi-finished goods and final products in warehouses and in production. Storage and loading.

Automation and MFC

Management of all your equipment as one unit. Semi- and fully-automated operations.

Just In Sequence / Just In Time (JIS/JIT)

Support for JIS/JIT supplier concepts from all automakers, daily deliveries, shipping and assembly in sequence.

“Don’t limit your plans to individual system components. Think through a comprehensive MOM solution covering logistics, quality and maintenance as one unit while connecting you with suppliers and customers.”

Rostislav Schwob Supply Chain Solutions Director

Base Your Decisions on Data

Capture reality in a virtual environment

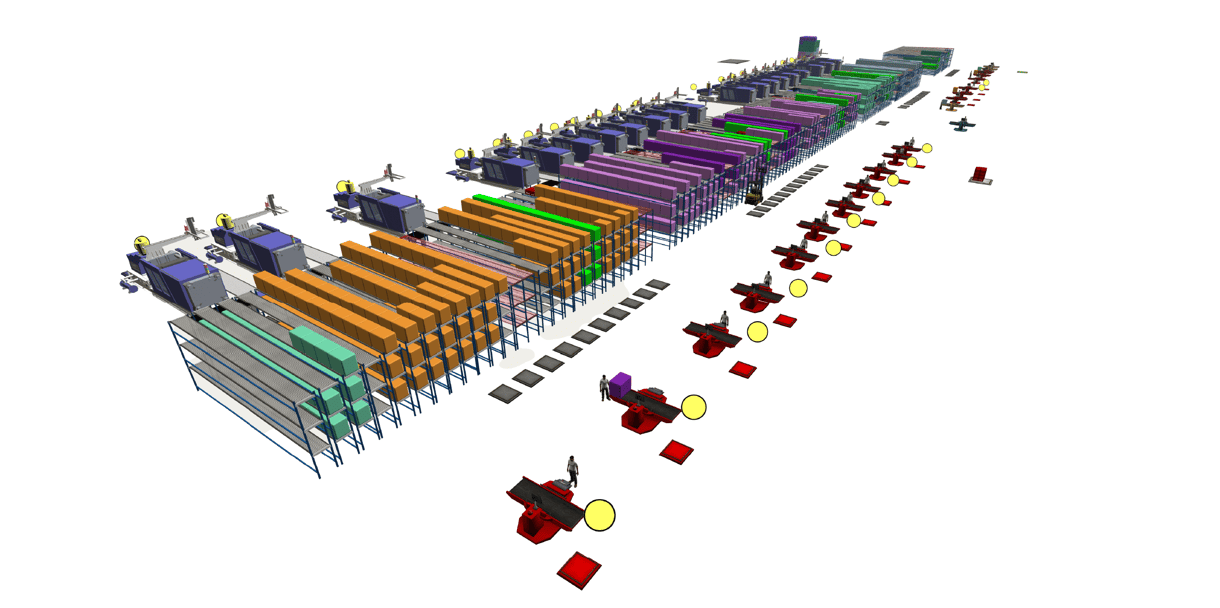

Real-time reporting provides an instant overview of your production and logistics processes in one place. Monitor performance down to the level of individual work centres. Get support for efficiently managing processes in your hall and motivating your workers. Use data visualisation in a digital twin to gain a quick understanding of the current situation and support for your decisions.

Optimize your processes by analysing and mining your data

Thanks to the analysis of historical data, you can uncover key patterns and bottlenecks in manufacturing and logistics. Expanding this retrospective with a prediction of your results for the next week or month will ease your decision-making. In addition, interconnecting analytical tools with other systems supports the automatic optimisation of warehouse operations and increases overall operational efficiency.

Model solution variants and gain a firm grasp of complex systems

Can't decide on a solution variant? Want to know the performance of a new design, or its critical points? Dynamic simulation in the FlexSim tool will answer your questions even before the project begins. You can verify and fine-tune every change during subsequent optimisation. FlexSim learns with the help of AI (reinforcement learning), enabling it to solve complex tasks almost in real time.

Interconnect MOM with other systems and technologies

SAP SOLUTION

MOM within SAP

A solution that makes use of your existing SAP system and its infrastructure and data.

OTHER SOLUTIONS

MOM system as a separate solution

Gain the benefits of a MOM solution inside Aimtec DCIx.

Visualise a real state and simulate the solution

Supplement your MOM solution with Zebra devices

Zebra Technologies offers a broad portfolio of automatic identification products and services. We’ll help you choose the right technologies.

Case study

A shift from paper to automated data collection and production planning

A comprehensive MOM solution for logistics and manufacturing has amplified plant efficiency at NOVASPORT. This customer gained a way to make predictions for a period of up to one year, simulate various scenarios and identify production bottlenecks.

Get in touch

Want to learn more about this solution? Contact an Aimtec specialist. They’ll show you all its specifics, along with examples of specific deployments.

Daniel Choc Senior Business Consultant