Products

Aimtec DCIx

Get deep control over your lines

and warehouses

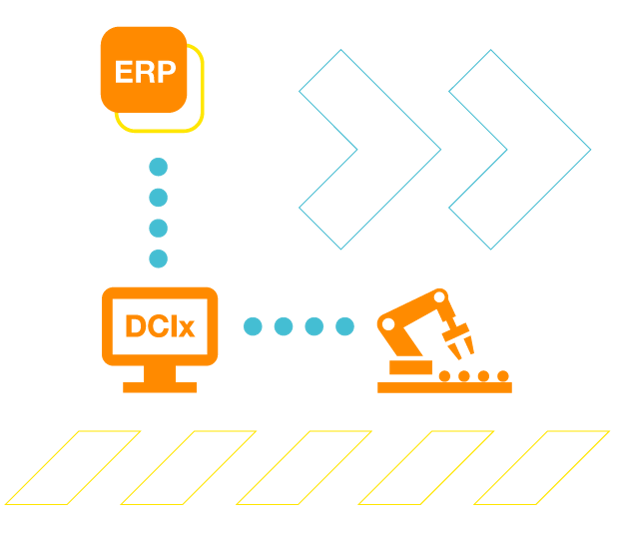

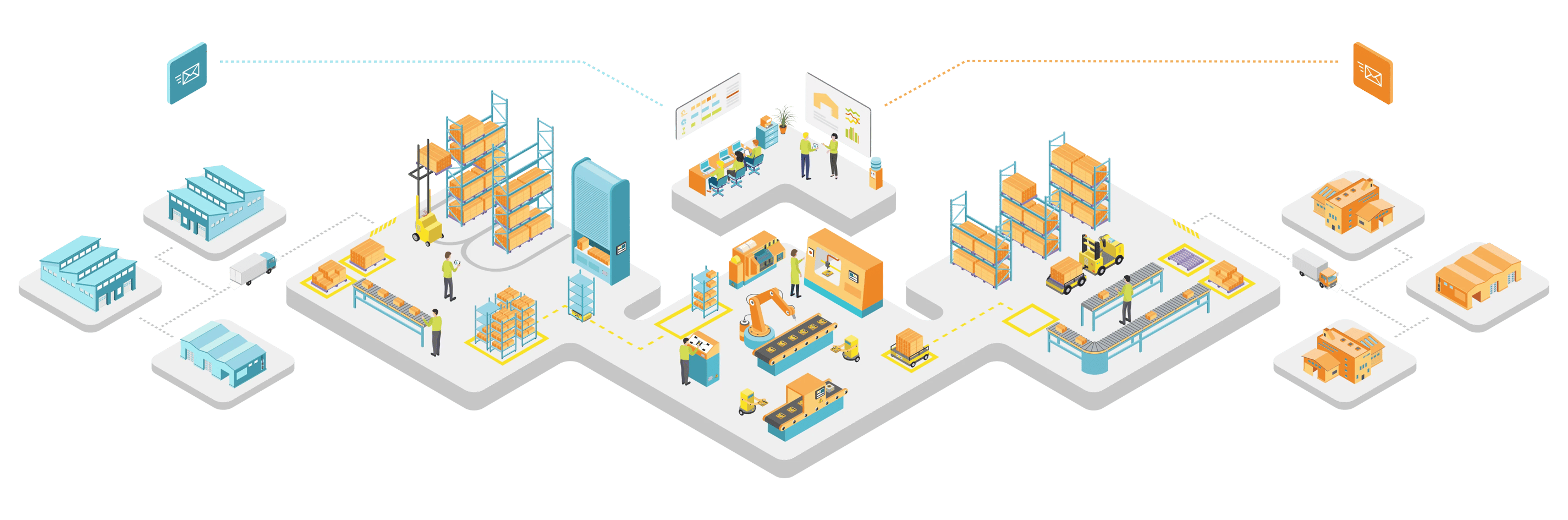

The Aimtec DCIx digitalisation platform is an intelligent layer linking your ERP system with the machines and processes on the shop floor. It interconnects your logistics, production, quality, shipping, automation technologies, machines and people. This horizontal and vertical integration lets you see your whole firm’s operations in an instant.

- 480+

- PROCESS TEMPLATES

- 7

- YEARS OF DEVELOPMENT

- 7/2

- SUPPORT

How will Aimtec DCIx help you?

MOM

Logistics

Manufacturing

Shipping

Reporting

Why Aimtec DCIx?

A digital image of reality

Instant on-line information is available for every phase of decision-making. Aimtec DCIx lets you share information throughout the chain from the supplier to you to the customer.

Speed and flexibility

Aimtec DCIx enhances ERP systems with features that increase solution flexibility and deployment speed. This solution is ready for use in individual sectors (automotive, plastics, engineering).

Deployment of Artificial Intelligence (AI)

AI helps to optimise the management and tasking of employees or to predict how a shift, week or month will turn out. Within dynamic simulation, it answers questions even before changes or projects are implemented. An in-app chatbot speeds up information retrieval.

Frequently Asked Questions

- Why centralise your control over machines, people and processes?

-

The machines at your plant may vary greatly in their ages and sourcing. So you maximise efficiency when you join them into one functional whole.

- Why integrate quality, manufacturing and logistics?

-

Your lines fall silent if logistics doesn’t feed the needed materials or your maintenance or quality people aren’t on time. Interconnecting every area eliminates downtimes and reserves.

- How do you introduce changes quickly and efficiently?

-

Adjust and reconfigure your system in-house. You can save your consultations for major changes only.

“A digitalisation platform works as a tool for constant development. You control your company, machines, technologies and people based on precise data in real time. This gives the flexibility, speed, and capability you need to respond with agility and without delay.”

Rostislav Schwob Supply Chain Solutions Director

Interested?

Want to learn more about Aimtec DCIx? Eager to see some example deployments? Contact our specialists.

What else do you get with Aimtec DCIx?

- Self-regulation

-

Your production facilities respond to changes in conditions automatically.

- Process management

-

You get a firm grip on logistics and manufacturing processes.

- Prediction

-

Trend analysis stops unexpected situations in advance.

- Configurability

-

The Process Builder offers an extensive process library.

- Cloud-native design

-

Aimtec DCIx was developed specifically for the cloud.

- Automation

-

You get integration and control of the technologies on the market.

- Nonstop operations

-

Predictive and self-repairing processes and technologies enable this system to run nonstop.

The smart integration with Aimtec DCIx will convince you

Aimtec won 1st place for its Aimtec DCIx solution in the prestigious Factory Innovation Award 2024 competition in the Resilient Factory category. In it, the jury makes the awards to companies that help their customers manage the impacts of supply chain disruptions – so that they can both respond to and prevent these fluctuations.

>> Read more

Case study

A sequencing solution and traceability for a global automotive supplier

Traceability for safety-critical parts with a level of detail down to serial numbers and monitoring and managing all manufacturing operations and processes along with sequencing checks – these were this project’s primary goals.

Get in touch

Want to learn more about Aimtec DCIx? Turn to an Aimtec specialist. They’ll show you further specifications, including example deployments.

Daniel Choc Senior Business Consultant