Solutions

Production

planning

Harmonise all your processes throughout

production and supply chains

Clear organisation for every operation

- Plan the entire production cycle in a single solution.

- Centralise your planning.

- Replace planners seamlessly.

- Respond to customer demands swiftly.

- Increase production throughput.

- Fulfil KPIs more effectively.

Our customers

Our solution’s benefits will win you over

Production plan optimisation

The solution prepares a feasible plan that guarantees flawless and timely order fulfilment.

Supply chain management

Expected orders, stock levels for each item and demand levels can be entered or imported from an external system.

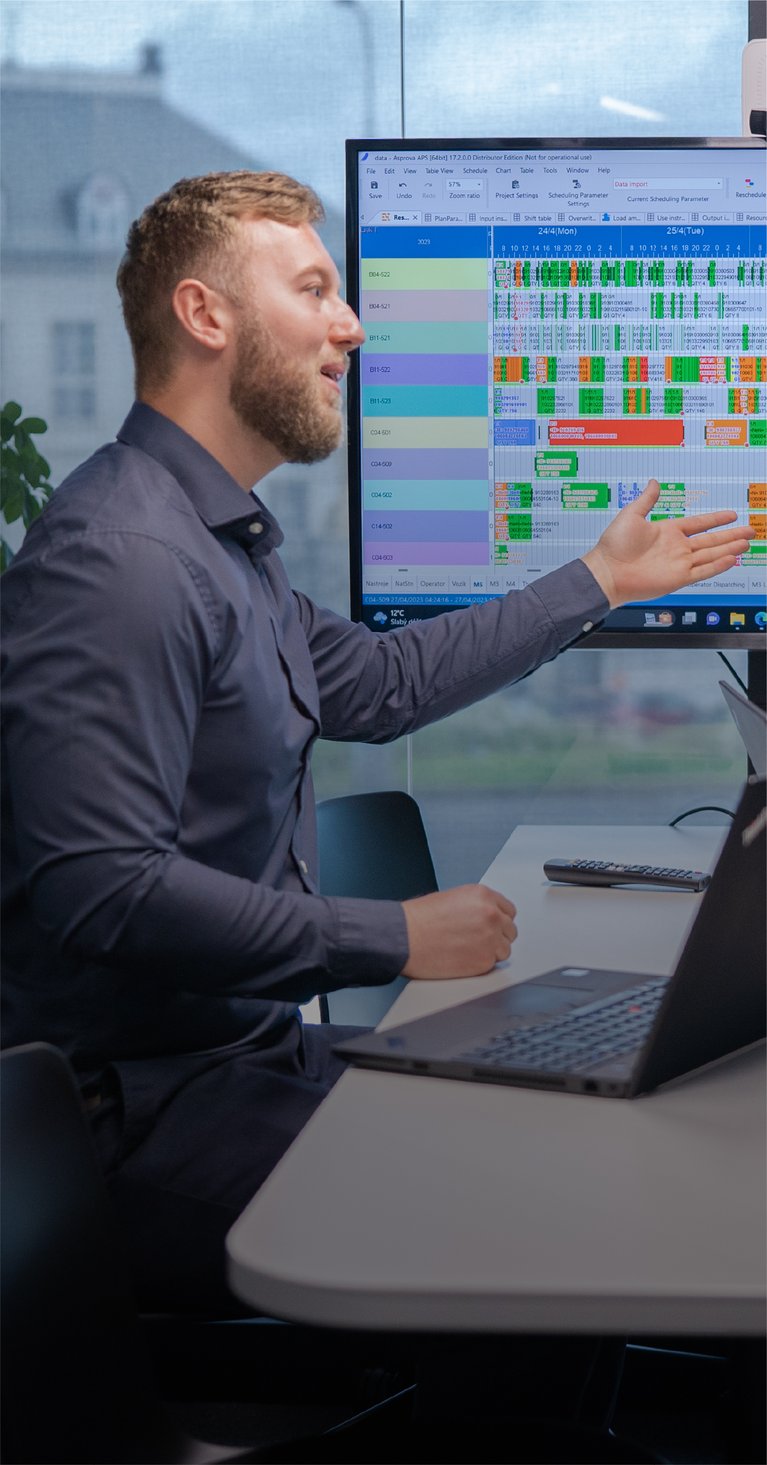

A clear work queue for individual work centres

Planners will be able to create capacity overviews for upcoming days and even a full year in advance for every work centre.

Forecasting for material purchases

Based on an optimised production plan, you receive a precise forecast for purchases of material.

Easy simulation of production plans

This solution lets planners simulate production plans freely. An intuitive what-if analysis helps them choose the one that’s most appropriate.

A precise headcount / labour plan

A balanced headcount plan can be generated based on a refined production plan.

Reflection of every imaginable production constraint

The planning system factors in every production constraint so that resources – machines, tools and people – never run out or burn out.

Always there for you

The autonomous client keeps you responsive even after working hours – with automatic scenario-based replanning during night shifts.

“Don’t waste time creating production plans by hand. Take advantage of optimised tools that can find a more effective combination of manufacturing operations – and can also deal with unexpected changes to supply and demand.“

Otakar Horák APS Services Manager

Plan production and optimise your production plan efficiently

SAP SOLUTION

Production planning as a part of SAP

Create a production plan in an interactive planning table using a variety of strategies for arranging production commands.

OTHER SOLUTIONS

An tool for advanced planning and scheduling

With Asprova APS for advanced planning and scheduling, you can plan across all of your work centres.

Supplement your solution with Zebra devices

Zebra offers a broad portfolio of products and services for automatic identification. We’ll help you to choose the best technologies.

Case study

Digitalising the planning of one of the toughest manufacturing processes

Magna manufactures plastic components for passenger cars. This company has some of the toughest and most complex manufacturing processes in the industry. Asprova APS provides efficient planning at Magna.

Aimtec Insights

Get in touch

Want to learn more about this solution? Contact an Aimtec specialist. They’ll show you all its specifics, along with examples of specific deployments.

Václav Kalina Business Consultant Production Planning Solutions